6:20 PM Penn Engineers 3D Print Smart Objects with " expressed logic" | |

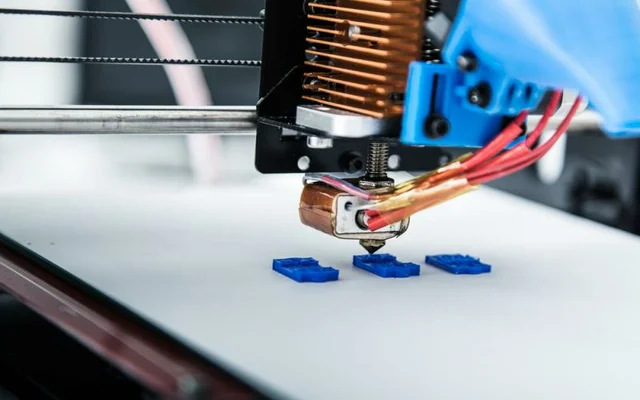

Including without a brain or nervous system, the Venusian Flycatcher, similarly, perceives difficult conclusions about when to shut the probable prey, and even find out when she accidentally found something, in fact that she does not have the opportunity to eat. Scientists from the Pennsylvania Institute of engineering and applied Sciences Secondary school draw inspiration from these systems. Applying stimuli-responsive materials and geometric bases, they designed structures that " embodied logic."Only thanks to their own physiological and chemical composition, they have every chance to qualify which of the countless possible reactions goes in the footsteps to do in response to the environment around. Not paying attention to the inaccessibility of motors, batteries, circuits or microprocessors of any kind, they have every chance to switch between several configurations in response to specific signals in advance located around the environment, these as humidity or chemical preparations on an oil base. Using multi-material 3D printers, scientists have all the chances to make these functional structures with embedded logical substances if/then and have all the chances to keep under control the time of any shutter, in fact that allows you to do difficult mechanical behavior in response to the usual configuration in the surrounding environment. For example, applying these basics, it is possible to construct a device of the forecast of pollution of the Aqua environment for dissection and sampling only the best chemical products on the basis of the oil and at a temperature of higher specific threshold point. Penn engineers released a study of open access with a statement of their own layout in the journal Nature Communications. The study was conducted under the direction of Jordan Rainey, associate Professor of mechanical engineering and applied mechanics Penn Engineering, and Ijo Jiang, postdoctoral researcher in his laboratory. Lucia Korpas, a graduate student at Rainey's lab, has also made a personal contribution to the study. Rainey's lab is interested in structures that are bistable, which actually means they have every chance of containing 1 out of 2 configurations infinitely. He is still interested in responsive materials that have every chance to change their own form under the right circumstances. These opportunities are not morally connected with each other, but the "severe logic" relies on both. "Bistability is guided by geometry, while sensitivity comes from the chemical qualities of the material," says Rainey. "Our alignment uses multi-material 3D printing to bridge through these individual fields, such as actually that we can apply the fabric response to the change in the geometric characteristics of our structures in suitable instructions." In previous work, Rainey and his co-worker showed how to 3D-print bistable gratings from angular silicone beams. When pressed together, the beams remain fixed in the buckled configuration, but have all chances of simply being pulled back into their expanded shape. This bistable behavior is almost entirely dependent on the angle of the rays and the case between their width and length," says Rainey. "Grid compression protects the elastic energy in the material. If we were able to apply the environment around us to the configuration of the beam geometry in a controlled manner, the structure would cease to be bistable and would necessarily release its own accumulated destruction energy. You would have a drive that does not need electronics for such in order to qualify in case and when the excitation should happen." Shape-changing materials are common, but fine-grained control over their transformation is more difficult to achieve. "Almost all materials eat water and expand, for example, but they expand in all instructions. This can not help us, due to the fact that it actually means that the correspondence between the width and length of the rays remains unchanged," says Rainey. "We needed a method to limit expansion to only one direction." The conclusion of the survey was in order to fill their own 3D-printed structures with glass or cellulose fibers running parallel to the length of the rays. Like carbon fiber, this inelastic skeleton pre-empts the beams from stretching, but permits the space between the fibers to expand, increasing the width of the beams. With this geometric control on the space, more subtle form-changing reactions have all chances to be achieved by the method of varying the fabric beams are manufactured. Scientists have made functional structures by using silicone, which eats oil, and hydrogels, which eat water. It would also be possible to use heat-sensitive and light-sensitive materials and develop materials that respond to even more specific stimuli. Changing the initial ratio of the length and width of the rays, and even the concentration of strict internal fibers allows the surveyors to produce drives with different levels of sensitivity. And due to the fact that the method of 3D-printing prospectors allows you to apply all kinds of materials in one and the same print, the design has the ability to own a number of form-changing answers in different areas, or including are in order. "For example," Jiang talks, " we showed alternate logic by constructing a box that subsequently, under the influence of a favorable solvent, has the ability to open independently and then lock itself through a given time. We have come up with an artificial origin Venus Flycatcher, which has the ability to lock only in that case, if the mechanical load is applied in the direction of a specific time interval, and the box, which opens only in the presence of oil and water." Like chemical properties, such as geometric and pronounced components of this natural alignment is not dependent on scale, actually what it means, exactly what these basics still have a chance to be applied by the structures in microscopic volumes. "It has the ability to be great for applications in microfluidics," says Rainey. "Instead of this, in order to apply a solid-state sensor and a processor that every day reads what actually flows into the microfluidic chip, we would have been able, for example, to design a gate that is mechanically locked, if it detects a specific pollutant." Other probable use was able to connect the detectors in remote, austere surrounding environments, like desert, mountains, or including any other planet. Without the need for batteries or computers, these integrated natural detectors stand a good chance of being inactive for many years without human interaction, only when they are presented with the right environmental signal. | |

|

| |

| Total comments: 0 | |